Straight Tuck End

Choosing the right kind of packaging is an essential part of achieving business efficiency as the mismatch between the offerings and their packaging can prove to be quite a disappointment for the business as well as the customers. An important part of the overall marketing mix for a product, it has been stressed upon time and again that the packaging style, color and font play a major role in influencing the customer purchase intention at the point of purchase. The ideal packaging structure needs to be aligned with the offering's shape, be sturdy enough to maintain the quality and uniqueness of the offering and be complementary to the business capabilities. It is not feasible for a small scale business to choose a packaging style which runs best on assembly line machines as such packaging's can be quite hard to perfect, manually. Moreover, it is no longer enough for a box to merely accommodate the product but to also complement the overall product concept. TheCustomBoxes.com.au offers packaging options that support the creation of uniqueness and functionality simultaneously.

Request a Quote

Request your quote in a few simple steps. Share personal details and here you go!

Leave your personal details here. Our experts will approach you soon:

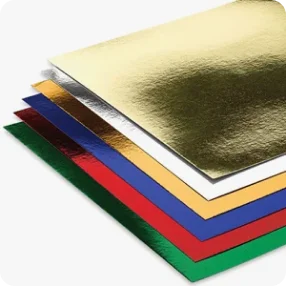

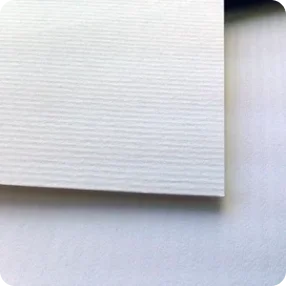

Material / Paper Stock We Use

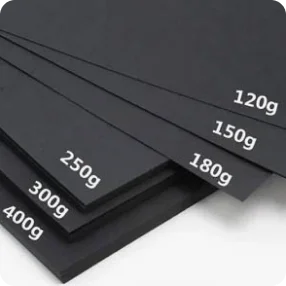

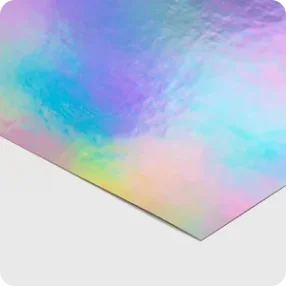

When packaging is meant for protecting and prompting products, the material/paper stock ensures integrity and safety. Well-known cardboard packaging material is synonymous with durability and resilience. Kraft is delicate to take care of your fragile items. Corrugated boxes are tough to bear the tear and shear of external stresses. We have arranged the world’s finesse stock of papers full of qualities; sustainability, affordability, and elegance.

Duplex Chipboard

Grey Chipboard Cardboard

Black-Kraft

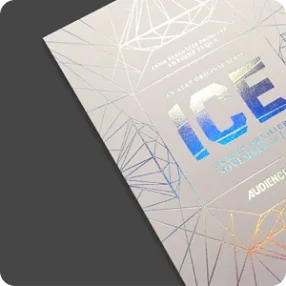

Holographic

Metallic Paper

Natural Brown Kraft

SBS C2S

Textured

White Kraft

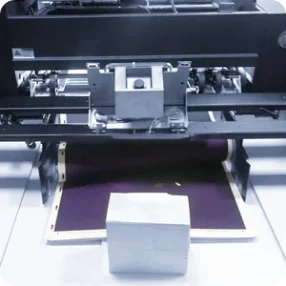

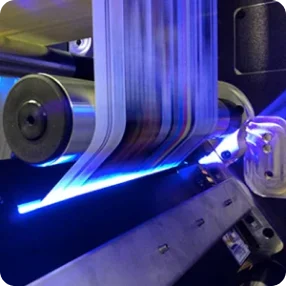

type of Printing Methods We Use

We all have stepped into the world of digitalization. The packaging and printing have also been digitalized. Digital printing on blank eco-friendly surfaces of boxes delivers a sense of creativity. The offset printing method, though traditional yet classic, ensures consistent image resolution. The screen printing allows textured prints inside and out of the boxes. We offer all the latest types of printing methods to imprint all your thoughts on custom boxes.

Digital Print

Offset Print

Scodix Digital Enhancement

UV Print

type of inks We Use

Joyful prints and consistent brand images all are blessings of the vibrancy of printing inks. We have a wide variety of in-stock inks including funky Pantone, shiny Pantone Metallic, smooth oil-based inks, and sparkling fluorescent color ink. For bold and bright options, explore soy vegetable inks and water-based inks. Ignite your creativity- brush your ideas Now!

Fluorescent Color Inks

Oil Based Inks

Pantone

Pantone Metallic

Soy Vegetable Based Inks

Water Based Inks

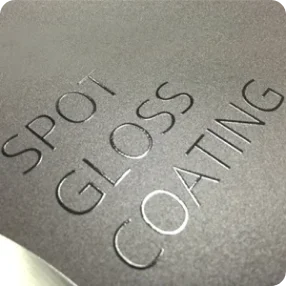

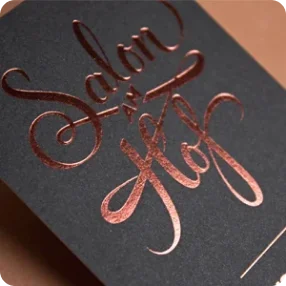

Our finishing

Finishing is considered to have a crucial impact on overall aesthetics. At The Custom Boxes, we view it as more than just an eye-appealing factor; it's a statement. Customized packaging simply radiates brilliance. Based on your preferences, we can add a touch of glamour with glitter on a metallic finish. We infuse a sense of exclusivity through silver and gold foiling or coating on custom packaging. Explore the myriad of options available – discover more now.

Anti Scratch Lamination

Aqueous Coating

Lamination

Soft Touch Coating

Soft Touch/Silk Lamination Cards

Spot Gloss UV

Add- ons

We assist you in elevating beyond ordinary packaging. Add-ons are artistic touches that captivate customers' attention. These extras work wonders in enhancing the perceived value of boxes. By adding glamour to your custom packages, they also enhance functionality. Embossing, debossing, foiling, screening, PVC windows, and inserts not only ensure the safety of products but also ignite excitement in every unboxing adventure.

Cold Foil Printing

Debossing

Embossing

Full Embossing

Hot Foil Stamping

Proper Embossing

PVC Patching Cards

Ribbon Handles

Specifications

We give you complete freedom to tell your brand tale via dazzling packaging prints. Well, we don’t know what you want unless you specify us. It’s a give-and-take process; select box dimensions, choose material, and upload pictures of the most inspiring packaging. In return, we will deliver your dream packages. Fill in the specifications and get a chance to win your business game.

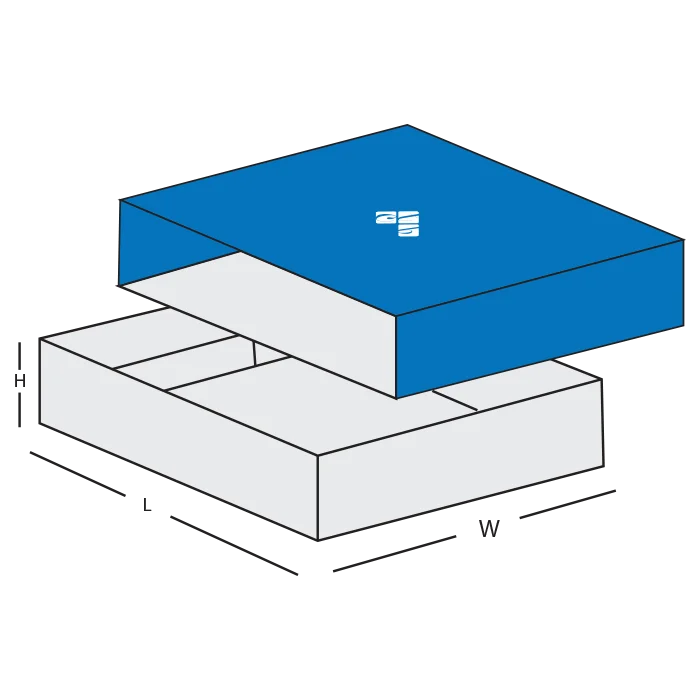

| Dimensions | All Custom Sizes & Shapes |

|---|---|

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 - 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 4-6 Business Days , Rush |

Straight Tuck End Boxes and Packaging

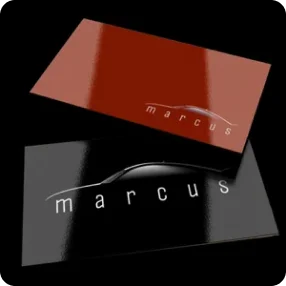

The STE, short for Straight Tuck End, is a packaging structure which is preferred by most kinds of businesses. This is because it can be assembled manually as well as mechanically. The concealed glue flap is attached to one of the side panels making it more sophisticated-looking than the other variations that have raw cutting visible in the front. This gives the front of the box room for a window panel display, which is an eye-catching packaging feature for many businesses like cosmetics, food items and toys. Typically, the closure panels of the top and bottom of the box can be tucked from front to rear and vice versa, making the exterior more pleasing to the eyes. Moreover, the window film and the side tucks do not interfere, as in the case of Reverse tuck end (RTE) style, making it more functional and appeasing.

Free Design

Do you remember the last time you went into a shop and thought if I would have designed this box or something else it would look like so much better? At TheCustomBoxes.com.au, we offer you a chance to perfect your Custom straight tuck end boxes to your own liking from its finishing to designs you want to create. The finishing that we offer are Glossy, Matte, Aqueous Coating, Spot UV. You can also avail our add-ons such as Die cut window, gold foiling/silver foiling, raised ink, embossing and debossing. After all it is all about you.

Printing

What makes card board boxes ideal for packaging is that they are great when it comes to printing. All the decoration, printing and designing becomes much easier. They can turn out to be great when it comes to marketing and creating brand awareness. The cherry on the top of it all is the fact that we use digital printing, offset printing and onscreen printing methods along with CMYK and PMS color selection tools.

Quality Cardboard Material

Custom straight tuck end boxes mostly contain gift items and tend to be moved here and there which is why they need to be practically sound. Remember the last time mobility caused any damage to your box or what it contained? Don’t worry we have standard silk card, biodegradable, and recyclable craft with the thickness of cardboard material varying from 280 GSM to 550 GSM. These cardboard boxes serve the diverse needs of customers and prove to be smart packaging solution.

Fast Turnaround

From the time you make the order, the process of producing, packaging and delivery takes only 10 to 12 business days to be at your door step. We all love our customers which is why we believe in providing you with super quality and perfect quantity right on time.

Free Shipping

Australia enjoys free shipping of Custom straight tuck end boxes whether it is in bulk or small amount. In case you are in rush, you can avail our rush delivery service in Australia at an extremely reasonable rate.

Frequently Asked Questions

A single platform to manage your end-to-end packaging workflowBelow you'll find answers to some common questions around creating a custom box. Every order is little different though, so don't hesitate to reach out with anything else you might be wondering.

We fully comprehend that packaging boxes not only present but also promote products effectively. Crafting a unique brand voice requires a fresh and innovative appearance. 'Box by Style' stands out as a distinctive feature on our official website, guiding you in selecting the perfect style for your delicate, high-selling items. Assemble various pieces of cardboard or other packaging materials to experience the final result. We infuse delight into every unboxing through exceptional interlocking. Explore creative concepts and captivate your customers with playful shapes without compromising functionality.